The result of a multidisciplinary research

The BWG™ developed in collaboration with the major galvanizing associations all over the world.

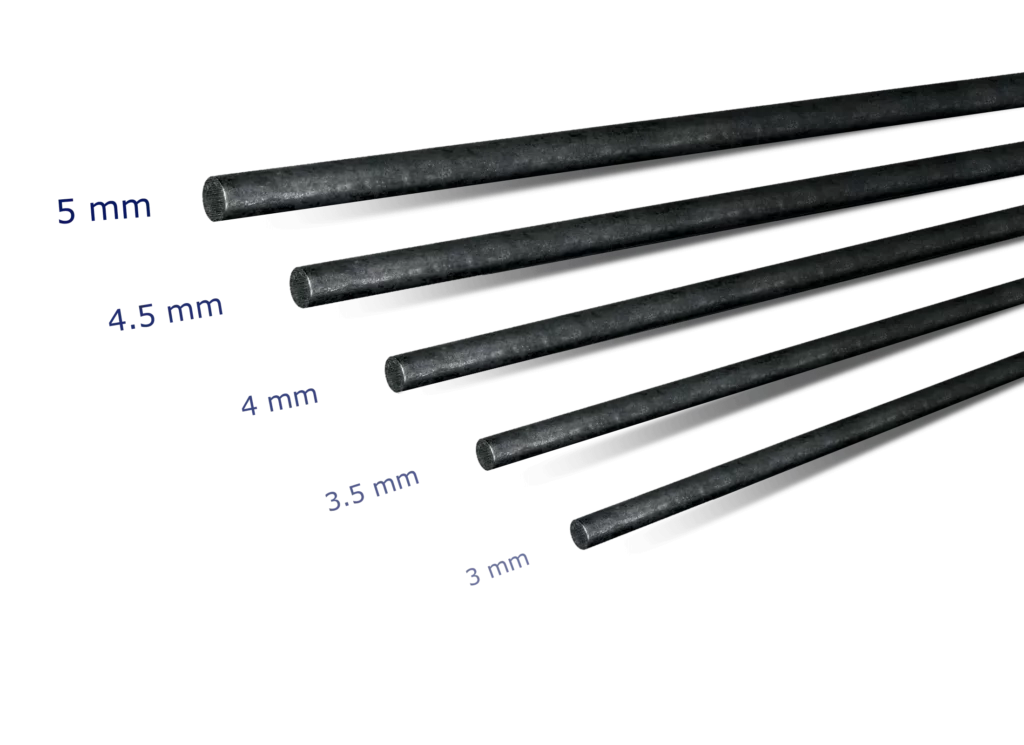

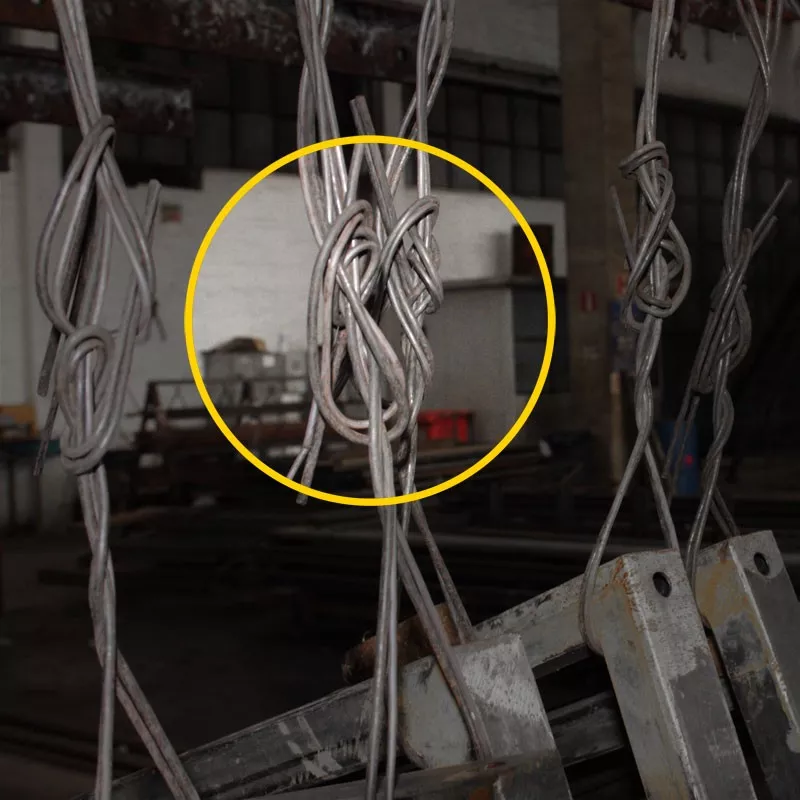

A more pliable Wire

The malleability of the wire makes the binding operations easier and it allows to improve the productivity by 30%.

Why choose BWG™ for your galvanizing plant?

- The lowest zinc

absorption ever seen - Improved tensile strength

and elongation standards - The most pliable

wire ever

How did we develop this wire?

Bottaro has been working for years with the major companies and associations in the Hot-dip Galvanizing Industry to optimize the BWG™ wire.

All eyes on our BWG™

BWG™ appeared in various newspapers and magazines all over the world: you can read and download all articles here.

Download our technical studies

We kindly ask you to fill in the fields hereunder to receive a the copy of the technical study made in collaboration with the Polytechnic University of region Marche and consult the test results.