Baling machine: why choose 1,000 kg coils

Discover how 1,000 kg coils can revolutionize your operations: productivity, storage, safety, and ease-of-use advantages, along with useful tips for adapting your baling machine and preserving material properly.

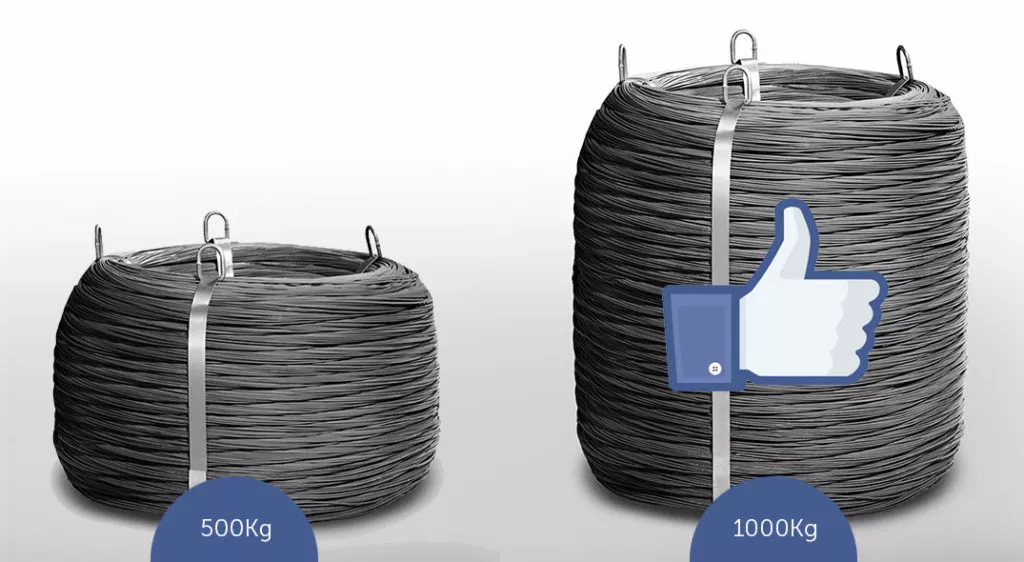

1,000 kg steel wire coils are becoming the preferred choice for a growing number of companies in Europe due to their significant advantages in terms of productivity, storage, and safety. However, for many customers accustomed to 500 kg coils, transitioning to larger formats requires some technical adjustments to their baling machines. This article explores not only how to adapt the baling machine but also the key reasons to choose 1,000 kg coils.

Why Many Customers Still Choose 500 kg Coils

- Reduced space requirements under the baler: Compact dimensions fit well in confined spaces.

- Established habits: Many customers are accustomed to working with this solution and have not considered alternatives.

- Compatibility with pay-offs: In some baling machines, shorter pay-offs prevent the use of taller coils, increasing the risk of wire tangling during unwinding.

- Logistical simplicity: Two 500 kg rolls can be stacked and safely transported on a pallet.

Why Choose 1,000 kg Coils?

Despite established habits, transitioning to 1,000 kg coils offers tangible benefits that improve baling and storage operations.

- Increased Productivity: 1,000 kg coils reduce the frequency of replacements, minimizing machine downtime. Greater operational continuity translates into increased production efficiency.

- Optimized Storage Space: Larger coils allow storage space to be halved compared to 500 kg rolls. For instance, 40 rolls of 500 kg can be replaced by 20 rolls of 1,000 kg, keeping the amount of material available unchanged. This advantage is particularly beneficial for warehouses with limited space.

- Improved Transportation Safety: 1,000 kg coils are delivered on pallets and strapped to ensure stability during transport. This solution reduces the risk of damage or accidents during handling.

- Ease of Use with XSystem: Customers can place the pallet equipped with the XSystem directly under the baler, eliminating the need for a wheeled platform. This system ensures smooth wire unwinding without misalignments or jamming.

Adapting the Baling Machine to Use 1,000 kg Coils

For customers interested in transitioning to 1,000 kg coils, some baler adjustments may be necessary:

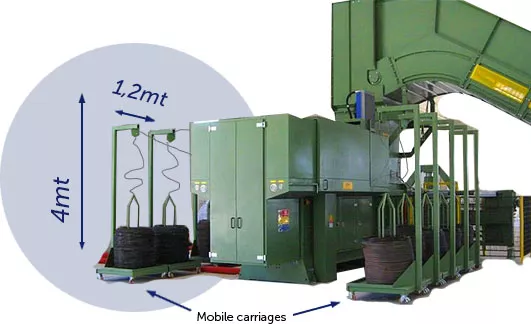

- Pulley Modifications: Increase pulley height from 2 to 4 meters to ensure smoother wire unwinding.

- Optimal Spacing: Maintain at least 1.2 meters between structures and 15–20 cm between each roll to facilitate strap opening.

- Mobile Carts or XSystem: If space under the baler is limited, using mobile carts allows for secure coil positioning.

- Coil Centering: Align the coil with the entry hole of the pulley to avoid wire tangling and disruptions.

If you have technical doubts, we recommend consulting the baler manufacturer or relying on our experts for tailored advice.

Storage and Maintenance: Practical Tips

In addition to proper use, coils must be stored correctly to ensure optimal wire performance during use. Proper storage helps preserve wire properties, ensuring smooth unwinding and avoiding issues during baling operations.

To maintain the wire’s properties and ensure optimal use, it is crucial to keep coils packaged until the moment of use. This precaution protects the material from:

- Moisture and dust: Preventing rust or contamination.

- Warehouse dirt: Preserving the original lubrication that facilitates unwinding.

A Strategic Shift to Enhance Efficiency

Switching to 1,000 kg coils is a strategic choice for companies looking to boost efficiency, optimize space, and ensure greater safety during transportation. With innovative systems like the XSystem and minor technical adjustments, it is possible to fully leverage the benefits of this solution. Contact us for tailored advice—our team is here to guide you through this change.

© Copyright Bottaro Mario S.r.l. - All rights reserved